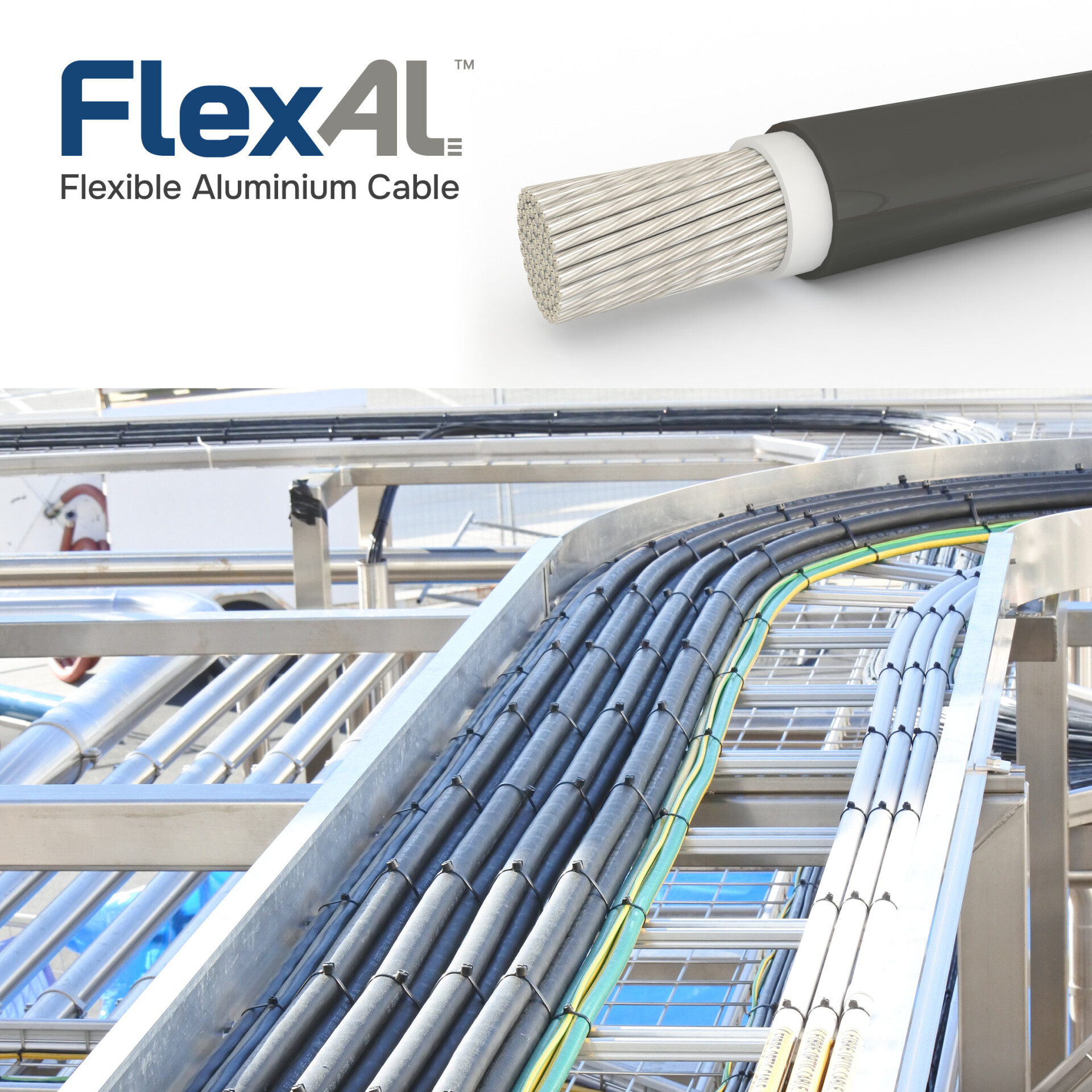

In a new purpose-built industrial processing facility, Electrical Connections provided its FlexAL cable solution for submain connections. The use of FlexAL facilitated an easy install option, while achieving significant cost and labour savings for the project.

Project Background

The facility required a reliable and efficient method to transfer power from the main switchboard throughout the factory. To meet this requirement, Electrical Connections supplied 1,200 meters of FlexAL 240mm cable, which was installed on elevated cable trays to provide power to various parts of the building.

Cost and Labour Savings

By selecting Electrical Connections FlexAL over traditional copper cable, the project achieved substantial financial savings. FlexAL's lightweight aluminium construction led to a direct material cost reduction of over $15,000. Additionally, the reduced weight of the cable enabled the contractor to cut labour needs in half, requiring only six labour hands instead of the twelve that would have been necessary for a copper installation of this magnitude. The ease of handling FlexAL, due to its flexible nature, further contributed to the project's success, reducing installation time and complexity.